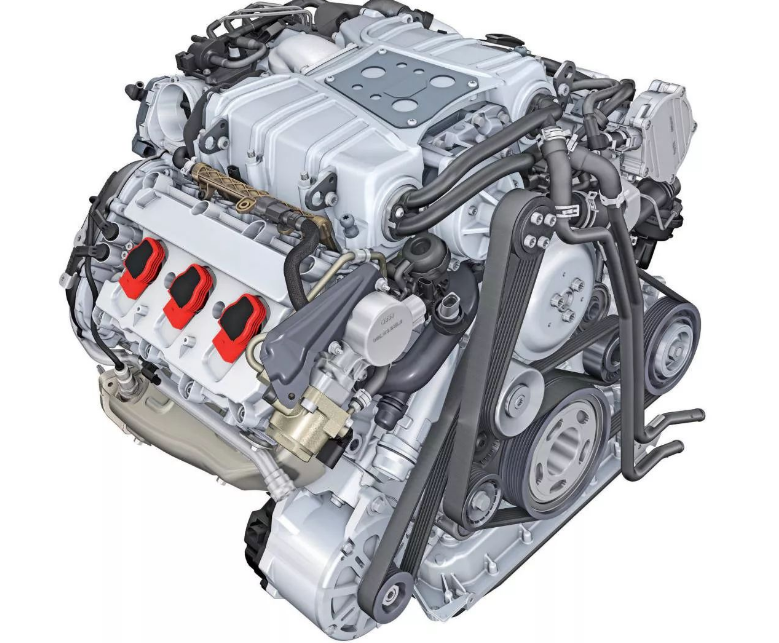

Ngokubanzi, i-injini ibunjwe ikakhulu yecandelo elinye, oko kukuthi, icandelo lomzimba, iindlela ezimbini eziphambili (inkqubo ye-crank yendlela enkulu) kunye nenkqubo ye-veling, inkqubo yokuphelisa, inkqubo yokupholisa, inkqubo yokuqalisa kunye nenkqubo yokuqalisa).

Phakathi kwabo, inkqubo yokupholisa njengenxalenye ebalulekileyo ye-injini,dlalaIndima engenakufikelelwa.

Xa umthamo wokupholisaihlwempu, ukuba uyilo lwenkqubo yokupholisa alunangqondo, i-injini ayinakuphola phantsi kwaye igqitywe ngokupheleleyo, eya kuthi ibangele i-quation engaqhelekanga, i-igning kunye nokuqalisa kunye nokuphikisana. Ukugqwesa kwamalungu kuya kukhokelela ekunciphiseni kweepropathi zoomatshini bezinto ezibonakalayo kunye noxinzelelo oluthe kratya, oluya kukhokelela ekulahlekelweni nasekufeni; Iqondo lokushisa eliphezulu kakhulu liya kwenza ukuba kubetha i-oyile, ukutshiswa kunye nokuhamba kwezemithi, ukonakalisa ifilimu yeoyile, ikhokelela ekunyuseni amandla, uqoqosho, ukuthembeka kunye nokuqina. Kwaye xa kukho amandla okupholisa kakhulu,

Ukuba umthamo wokupholisa wenkqubo yokupholisa womelele kakhulu, iya kwenza ioyile yendawo ye-cylindr ichithwe yi-feeds enxibileyo, i-Injini ye-injini iphantsi kakhulu, yandise ilahleko yeoyile, kwaye inciphise uqoqosho lwenjini.

Imoto ye-shacman yemoto iya kuyila kwaye iyongeze inkqubo yokupholisa, ngokweemodeli ze-injini eyahlukeneyo yokuqinisekisa ukuba i-injini yokusebenza inokugcina ukuba i-injini yokusebenza igcina ibhalansi yokusebenza, ukuthembeka kunye noqoqosho.

IXESHA LOKUQALA: Jun-12 ukuya ku-2004